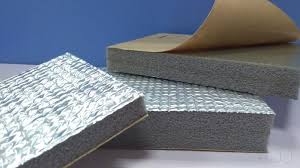

PE foam Melbourne is a lightweight closed-cell polyethylene (PE) foam, which is commonly used for cushioning, impact and shock protection, general packaging. It is a non-crosslinked foam which has a soft texture, and is available in different thicknesses to suit various applications.

During production, foaming agents are added to the melted polyethylene resin to generate a gas that enables it to expand into foam cells during the process of forming. The gas is typically nitrogen or carbon dioxide and can be produced in a chemical reaction of an exothermic blowing agent or through thermal decomposition of a neutral or unreactive blowing agent.

Closed cell foam is a very strong, resilient and versatile material which can be used as a protective padding for furniture, vehicles and other items. It is also used as soundproofing and insulation, particularly in walls, ceilings and roofs.

Gardiner Australia a wide range of polyethylene foam sheets in various densities, colours and thicknesses. These are dust-free, non-abrasive and inert and are resistant to common acids, alkalies, chemicals, fuels, oil and UV degradation.

We stock the medium firmness and density PE30 in sheet sizes of 2400x1200mm, with a product density of 30kg/m3. They are medium grey colour in thickness from 1.7 to 100mm and can be cut straight at your request to order lengths or widths.

EPE foam is a closed-cell, non-crosslinked polyethylene foam made from low density HCFC & CFC free polyethylene resins. It is lightweight, non-abrasive, chemically inert and environmentally 100% recyclable. It is widely used for basic foam packaging, tool storage trays floor underlay, furniture edge protection and water flotation applications.

These products are suitable for a wide range of applications and are available in anti-static and fire retardant grades on request. The product is stable, non-permeable to water and moisture, fungi, bacteria, air, and fuels and is moderately resistant to UV degradation in the outdoors.

Rotomoulding is an efficient method to produce plastic parts which are light weight yet rigid, and have enhanced insulation properties. It is an ideal solution for industrial tanks, bins and other containers which need a light weight, durable fully bonded structure to resist corrosion and maintain its integrity.

At Gardiner Australia team can help you achieve your goals with high-quality mouldings and custom-made moulds, designed to produce a wide range of industrial foam parts. Contact us to discuss your project and receive a quote.

We supply our customers with a wide variety of foam solutions, including polyethylene (PE) and expanded polyethylene (EPE). These are environmentally safe, versatile materials that can be recycled.